Our state of the art microscopy suite allows for detailed analysis of material physical properties, morphology, particle sizing and surface features, whilst our spectroscopy equipment reveals chemistry, elemental composition and bonding structures. Many of our services are UKAS accredited giving you further assurance of the quality of our analysis.

To find out more about the centre's facilities and capabilities, please visit our instrument portfolio page or contact a member of the scientific officer team at etc@brunel.ac.uk

Accredited Services

|

UKAS accredited services that are offered at ETC Brunel (lab nr 2245) include:

- Asbestos analysis of air filters, wipe samples, dust and bulk samples as well as liquid solutions

- Qualitative and Quantitative chemical analysis by SEM

- Qualitative analysis by FTIR

- Qualitative analysis by XRD

|

2245 2245

|

Morphology and surface features

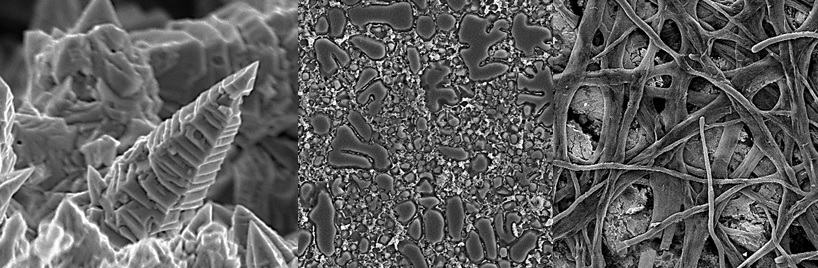

Our microscopy suite allows for detailed analysis of micro and nano-scale features at the sample surface as well as analysing the distribution of the material constituents within a sample.

Morphology, micro and nano-scale features / Topography

With our state of the art electron microscopy suit and extensive experience our microscopists can produce high resolution images of micro and nano-scale feature to allow you to better understand your materials characteristics. Atomic force microscopy also allows for 3D surface features to be measured for additional information.

Silver Paste

SEM image showing nano-particles in a thermal paste

Polymer fracture surface

Micro-scale plastic fracture and deformations

AFM topographic image

AFM image showing surface of diamond-like carbon coating on steel

Coating Thickness

Nano-scale coating thickness can be measured accurately using AFM

Chemical composition and bonding structure

Our facilities allow for chemical analysis of most organic and inorganic materials in order to determine composition and bonding structures of your samples.

Chemical composition

EDX mapping

Composition map of mineral section

EDX spectrum

Composition breakdown of specific surface area

Bonding structures

FTIR map

Compiled map highlighting filtered microplastics from wastewater

FTIR spectrum

Spectrum confirming different polymers present

Crystallographic

Using X-Ray techniques and ultra high resolution electron microscopy it is possible to determine and characterise structures of crystalline materials. From examining deposits in soil and clay samples, to discovering phases within metallics and their alloys, our range of equipment allows for detailed analysis of most materials.

Crystal structures and identification

Phosphor Structure

Single Crystal X-ray analysis of phosphor

XRD spectra

Spectra showing minerals present in rock samples

Grain distribution and orientation

EBSD of rolled tin

Grain size and orientation of rolled Sn

Grain Analysis

EBSD study of Mg alloy

Lattice structures and atomic spacing

TEM image of spinel

TEM image showing lattice structure in spinel

Failure analysis

The ETC provides an expert service in Failure Analysis of engineering components and products. Using combination of microscopy and spectroscopy, along with other analytical techniques, we can determine the underlying causes of failure; whether this be due to a weakness in design, material properties or, more commonly, the effect of operational or environmental factors.

We have experience in the investigation of packaging materials and systems, marine structures, road and rail transport equipment, aerospace engineering, microelectronic devices and general engineering components

Microplastics identification and quantification

Microplastics are particles of plastic less than 5mm in size. They can be categorised in two groups; primary microplastics are originally created as small particulates to serve a specific purpose and secondary microplastics which are created through the abrasion of larger plastic over time. In either case, microplastics can be transported far from their source and microplastic pollution is found in almost all environmental settings and media including water, soils, flora and fauna.

See our case study

Read more

The ETC in partnership with CGG Geoscience Laboratories provides a microplastic analysis service including rapid mass screening method for microplastic detection using automated mineralogy by QEMSCAN®, micro-FTIR and thermal analyses to deliver data on microplastic identification, composition, quantification and morphological classification. This workflow can deliver data from a large volume of samples significantly quicker (e.g. 5 days to analyse between 100 and 200 samples, dependent on scanning resolution) than existing manual and optical micropollutant identification techniques. This has huge time saving implications when data is needed to inform policy and guide decision-making.

This effective workflow is designed to help stakeholders, including industry, charities, NGOs, local authorities and government agencies identify high concentrations of microplastics and areas of plastic leakage and wastage where they may be entering the food chain or natural environment. In addition, this approach can be used to determine a ‘Microplastic Pollution Index’ to quickly identify pollution ‘hot spots’ with high concentrations of microplastics (e.g. close to fisheries, other food supply chains, local wastewater and drinking water supplies) and highlight areas which need attention for mitigation strategies or where pollution limits are being exceeded. This saves organizations time and money so that efforts can be focused on specific areas. A long-term monitoring service can be provided to show whether plastic concentrations are reducing in response to mitigation measures.

Please get in touch to discuss a bespoke work programme to provide solutions to your environmental challenges.